Sunnen HT-Series Tube Honing machines

Sunnen HT-Series Tube Honing machines

| Product Code: | Sunnen HT-Series Tube Honing machines |

| Availability: | 1 |

- $0.00

Sunnen manufacture a wide range of honing equipment for the hydraulic cylinder manufacturing and repair industries.

From hand operated portable hones to fully CNC operated machining centres, Sunnen has the solution to your bore sizing requirements.

Tube Honing Machines

A tube honing machine has a rotating abrasive tip for enlarging holes to precise dimensions. Sunnen’s versatile tube honing systems are designed for a wide range of industries and processes. Easy to use, Sunnen's all-electric tube hone is reliable and affordable.

All Sunnen systems are fully supported by experts from around the world. With a complete line of products and a knowledgeable staff, you can rely on us for parts, service, and support.

Finding the Right Application

Sunnen’s HT Series tube honing machines are designed for a wide range of industries and processes, from small-diameter precision parts to large diameter oil field instruments and tubes. These versatile systems boast features such as: a unique tool expansion and feed system that maintains close size and finish specifications; touch screens for easy programming; PC or PLC controlled stroke position, motion, stone feed and cutting; automatic bore geometry correction; and servo rack or chain drive.

Whatever your application – from aircraft components to cylinder liners to very large hydraulic sleeves – Sunnen has a high performance tube honing system for you.

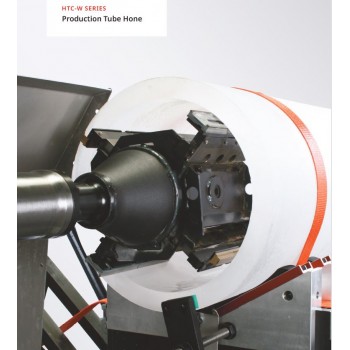

SUNNEN HTA SERIES TUBE HONE

Sunnen's HTA Series Horizontal Tube Hone is affordable and flexible yet has capabilities typically found in high-end systems such as a PLC-control with touch-screen interface for setting all machine parameters.

The machine is easy to set up and operate, even by less skilled operators. All setups are accomplished through the control panel at the front of the machine. There is no need to remove covers or doors to set vertical carriage positions as in some other machines. Please refer to the PDF Brochure above for further information and specifications.

MACHINE SPECIFICATIONS

- Diameter Range (I.D.): 64-533 mm (2.5 – 21 in)

- Diameter Range (O.D.): 610 mm (24 in) max

- Spindle Speed: 20-300 RPM

- Spindle Power: 2.24 kW (3 Hp)

FEATURES + BENEFITS

- Ideal for resurfacing and repair work where light-duty stock removal is needed, up to 0.030 inches (0,76 mm)

- Electromechanical stoker and spindle, features a Siemens servo stroker motor with belt drive for quiet and precise operation combined with a 3 Hp (2,24 kW) spindle unit

- Powerful Siemens PLC with color touch screen controls electrical functions of the system in conjunction with standard push buttons and a joystick

- Auto tensioning system includes a programmable auto tool feed that is standard. The abrasives can be fed up manually as well

- Works with Sunnen portable tooling for precise, accurate and consistent bore sizing. Bore diameter range: 2.5 - 21 inches (64 - 533 mm)

ADDITIONAL INFORMATION

The HTA is the first all-electric tube hone engineered specifically for hydraulic service facilities doing resurfacing and repair of actuators for construction, mining, farming and forestry equipment. It is also ideal for applications such as flow tube/meter run cleanup, extruder tube repair and other low stock removal jobs.

SUNNEN HTB SERIES TUBE HONE

The HTB-Series is a versatile tube honing machine that combines the best features of other Sunnen and General Hone machines. Precision sizing and finishing of long and large bores has never been easier or more productive.

MACHINE SPECIFICATIONS

- Diameter Range (I.D.) standard: 25 – 350 mm (1 – 13.8 in)

- Diameter Range (I.D.) optional: Up to 550 mm (21.654 in)

- Diameter Range (O.D.) standard: 60 – 400 mm (6.24 – 15.8 in)

- Diameter Range (O.D.) optional: 350 – 600 mm (13.8 – 23.6 in)

- Spindle Motor: 3 kW (4 Hp)

FEATURES + BENEFITS

- A PLC control and digital display allow complete control and monitoring of machine conditions

- A built-in load meter indicates high and low spots in the tube bore as the operator can adjust the stroke as required for optimum cycle time

- The operator can also work out tight spots in the bore when using the Short Stroke Cycle and Stroke Dwell features

- The Sunnen Modular Honing Tool System continually compensates for stock removal and stone wear to keep the machine running at peak efficiency at all times

- The HTB series is available in two-meter, four-meter, six-meter and eight-meter models, several different tooling systems are available depending on the specific application

- Lifetime application service with every machine purchase

ADDITIONAL INFORMATION

The HTB-S Series is a medium-duty tube hone the combines the best features of other Sunnen tube hones. Precision sizing and fi nishing of long and large bores has never been easier or more productive.

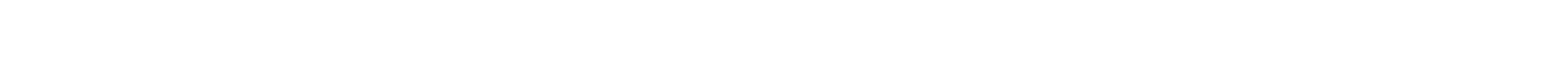

SUNNEN HTC SERIES TUBE HONE

A sophisticated CNC machine control makes the Sunnen HTC Series Tube Hones the best choice for small diameter bores in long workpieces.

MACHINE SPECIFICATIONS

- ID Range:25 – 1000 mm (1 – 40 in)

- OD Range (standard): 60 – 400 (2.4 – 15.8 in)

- OD Range (optional): 250 -600 mm (13.8 – 23.6 in)

- Spindle Motor: 7.0 kW (9.4 Hp)

FEATURES + BENEFITS

- Touch Screen programming eliminates confusion with multiple push-buttons. This and reduces setup time. Just touch the screen to input work piece specifications. The control recommends the proper tool and calculates the spindle speed. Most important, it will set the machine accordingly.

- To ensure quick set-up time, there is a fast retraction and expansion facility of the hone head, which is operated from the control panel. The HTC Control monitors the feed pressure and the spindle load to allow for maximum protection against overloading the tools.

- Special mode automatically corrects bore geometry errors.

- Quick carriage travel facilitates easy bore measurement and inspection, as well as the changing of abrasives and work piece.

- The standard workholding fixture device is universal, simple and has an O.D. range from OD 20 to 400 mm (.79 to 15.7").

- Lifetime application service with every machine purchase

ADDITIONAL INFORMATION

The Sunnen HTC Series incorporates a 2-axis Industrial PC for all control functions including stroke positions, motion control, stone feed and cutting pressure for optimum control of bore geometry. The HTC control reduces set-up time, making your job easier and more efficient.

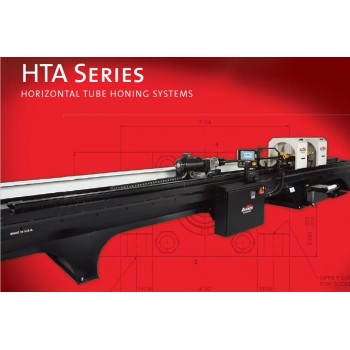

SUNNEN HTD SERIES TUBE HONE

Sunnen's HTD Heavy-Duty Tube Hone is built for demanding applications such as cylinder liners, hydraulic cylinders, extrusion cylinders, aircraft components and compressor components. The powerful system can remove more than 2,500 cm³/h. With a state-of-the-art touch screen control and power, tubes can be honed without bore drilling.

MACHINE SPECIFICATIONS

- Diameter Range (I.D.): 50 – 500 mm (2 – 20 in)

- Diameter Range (O.D.): 850 mm (33.5 in) max

- Spindle Motor: 22 kW (29.5 Hp)

- Servo Stroke Motor: 14.0 kW (18.75 Hp)

FEATURES + BENEFITS

- Automatic bore geometry correction

- 100 percent process control with tool overload protection

- 3-axis function control for stroke positions, stone feed, spindle speed and cutting pressure

- Variable stroke speed, adjustable in 0.1m/min increments

- Tool life for tool insertion and removal

- Front stationary steady rest shaft support

- Lifetime application service with every machine purchase

ADDITIONAL INFORMATION

The HTD can handle bore lengths from 4,000 mm (13.1 ft in) to 14,000 mm (45.9 ft). The system is easy to set up and stores more than 900 setups. The system recommends the required tool, sets the spindle speed and all cycle parameters. A new set-up can be made in two minutes.

SUNNEN HTE SERIES TUBE HONE

Sunnen's HTE-1600W Tube Hone is the company's first all-electric, cost-effective small diameter hone designed specifically for small diameter/long bore length parts. The machine produces ideal bore geometry and surface finish on small, long diameter bores as small as 4 mm (0.15 in).

MACHINE SPECIFICATIONS

- Diameter Range (I.D.): 4 – 20 mm (0.15 – 0.79 in)

- Diameter Range (O.D.): Dependent upon workholding options

- Servo Spindle Motor: .75 kW (1 Hp)

- Servo Stroke Motor: 2,17 kW (2.9 Hp)

FEATURES + BENEFITS

- 100 percent process control with tool overload protection

- One piece base design improves performance and decreases cost

- 3-axis function control for stroke positions, stone feed, spindle speed and cutting pressure

- Variable stroke speed, adjustable in 0.1m/min increments

- Traveling steady rest is standard

- Proven steel reinforced servo belt drive stroking system

- Optional safety system consisting of light curtain and fencing

ADDITIONAL INFORMATION

The HTE features a one-piece base design that aligns tool and part. A special feature of the feed system provides maximum protection against tool overloading that often leads to breakage. Tool specific force limits and run settings are stored in the Windows-based touchscreen control. A unique feed control system senses tight sections in the part and automatically corrects them.

SUNNEN HTG SERIES TUBE HONE

The popular HTG Tube Hone recently received a system update which includes the new Smart-Feed precision tool feed system for optimized performance and increased stock removal rates.

The Smart-Feed precision feed system combines the power of hydraulics with the finesse of a technically advanced control that includes servo position and servo force control. This results in more consistent bore size and finish from end-to-end for heavy-duty, long-bore honing applications.

MACHINE SPECIFICATIONS

- Diameter Range (I.D.): 50.8 – 609.6 mm (2-24 in)

- Diameter Range (O.D.): up to 660,4 mm (26 in) standard; up to 1219,2 mm (48 in) optional

- Spindle Motor: 29.83 kW (40 Hp) max

- Stroke Motor: 13.42 kW (18 Hp) max

FEATURES + BENEFITS

- Twice the stock removal rate ... up to 244 in3/hour

- Twice the I.D. capacity ... up to 24 inches

- Increased O.D. capacity ... easily handles up to 30-foot tubes (longer lengths optional)

- A new proportional load control system transfers power where it is needed ... up to 40 Hp to the spindle

ADDITIONAL INFORMATION

Sunnen's HTG series heavy-duty tube hones are built rugged for the high-production requirements of the oil and gas industry. The HTG series has twice the stock removal rate and double the part capacity of Sunnen's popular GH-210 tube hone.

Made in the U.S.A., the HTG series tube hone comes in two standard model sizes -- the HTG-4000 with a 4-meter (13.12 ft) stroke length and the 10-meter (32.81 ft) HTG-10000. Built-to-order machine sizes include 6-,8-,12-, and 14-meter stroke lengths.

With more speed, more power and more precision, the HTG series could bring more profits.

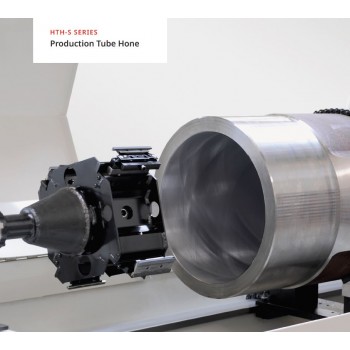

SUNNEN HTH SERIES TUBE HONE

The HTH-Series is a versatile tube honing machine that combines the best features of other Sunnen and General Hone machines. Precision sizing and finishing of long and large bores has never been easier or more productive.

MACHINE SPECIFICATIONS

- Diameter Range (I.D.): 25 – 1000 mm (1 – 40 in)

- Diameter Range (O.D.): 60 -400 mm (2.4 – 15.8 in) standard; 350 – 600 mm (13.8 – 23.6) optional

- Spindle Motor: 6.0 kW

- Spindle Speed Rate: 15-450 RPM

FEATURES + BENEFITS

- A PLC control and digital display allow complete control and monitoring of machine conditions.

- A built-in load meter indicates high and low spots in the tube bore as the operator can adjust the stroke as required for optimum cycle time.

- Operator can also work out tight spots in the bore when using the Short Stroke Cycle and Stroke Dwell features.)

- The Sunnen Modular Honing Tool System continually compensates for stock removal and stone wear to keep the machine running at peak efficiency at all times.

- The HTH series is available in two-meter, four-meter, six-meter, eight-meter, and ten-meter models. Several different tooling systems are available depending on the specific application.

- Lifetime application service with every machine purchase.

ADDITIONAL INFORMATION

The HTH-S Series has now more power and an easy set-up control with wide 10.4” colour touch screen panel. With the 6 kW spindle drive system and the 4-step gearbox the HTH-S ensures maximum power in the whole diameter range (up to 800 cm3/h).

In addition the system works with a belt driven tool drive which guarantees smooth working conditions and shock protection for the gear box. It is the first system of its kind which offers high flexibility on a production level.

Together with the Sunnen tools, abrasives and coolant oils all the HTH-S systems are working at their top performance and will meet customized production demands.

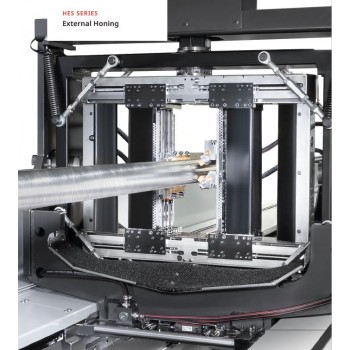

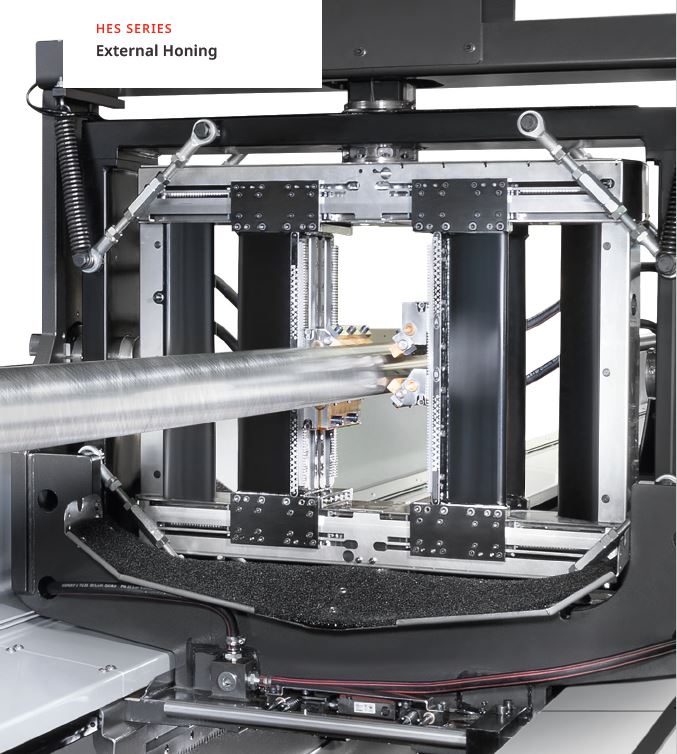

SUNNEN HES SERIES EXTERNAL TUBE HONE

Sunnen‘s first generation of external honing machines has been developed to meet the continuously increasing demands of the industry. Workpieces in the offshore, energy production and aviation sectors are exposed to extreme environments. Therefore electroplated hardchrome or plasma-spray coated surfaces are in operation.

MACHINE SPECIFICATIONS

- Spindle motor 16 kW / 22 HP

- Diameter Range (O.D.): 50 – 450 mm

- Stroke length up to 12‘000 mm

FEATURES + BENEFITS

- Large diameter range

- Automatic correction of roundness and parallelity

- Operator-friendly, Windows ®-based monitoring system

- Tool overload protection

- Easy operation with industrial touch screen

- Programmable dimension monitoring

ADDITIONAL INFORMATION

The new Extreme Hone Machine cuts nearly all advanced materials without trouble, next to mild steel. Sunnen built an outstanding control with maximum comfort and safety as a result of over 30 years of experience.

Please refer to the above pdf brochures or Email us for further Information and Specifications: info@kerzan.co.nz